If you plan on using an air tool, FRLs are a must to ensure long-lasting efficiency and peak performance.

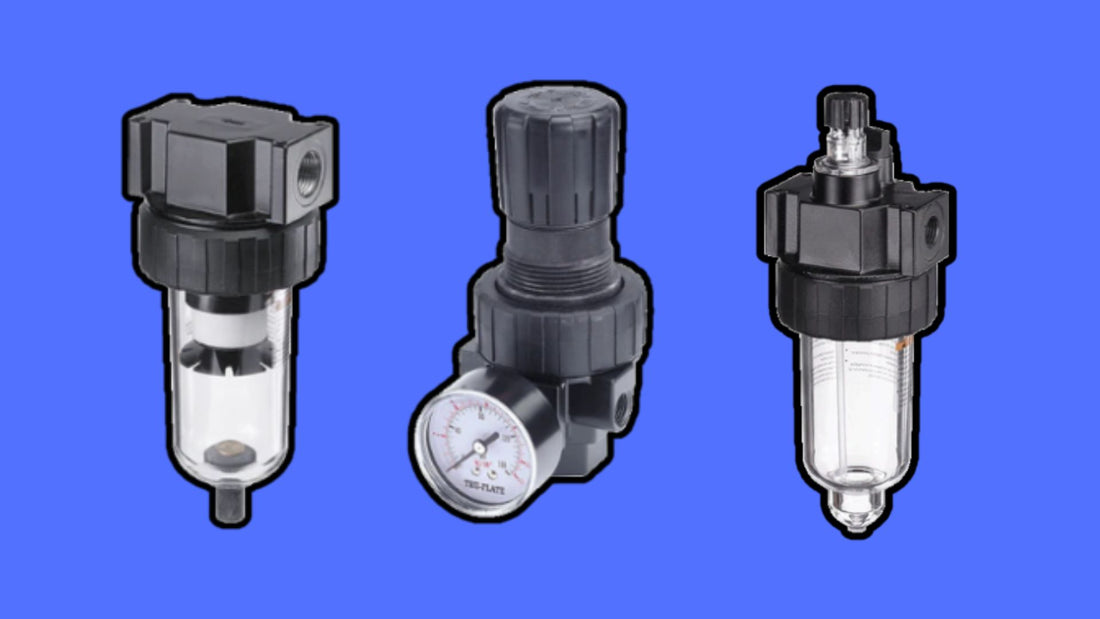

FRLs (Filters, Regulators, and Lubricators) provide point-of-use control of air pressure and cleanliness in pneumatic systems. Working like a pit crew, these three components work together to keep your pneumatic tools operating at their best. Let’s break down the individual functions of FRLs.

Filters: Your First Line of Defence

Filters remove impurities and contaminants from the compressed air, such as dust, dirt, oil, and water vapor. These impurities can cause significant damage to pneumatic components, leading to increased maintenance costs and reduced operational efficiency.

Regulators: Precision in Your Hands

Regulators allow operators to set and adjust the incoming air to desired pressure levels, ensuring that the equipment operates within safe and efficient limits. Regulators are essential for precision and consistency in pneumatic applications.

Lubricators: The Unsung Heroes

Lubricators introduce small amounts of clean oil into the compressed air stream. This lubrication serves to reduce friction, prevent wear and tear, and extend the lifespan of moving parts within the pneumatic system.

So, there you have it – the magic of FRLs. Working behind the scenes, FRLs allow air tools to run smoothly, reduce downtime, and increase operating longevity. TRUCKPARTSONLINE.NET offers a variety of FRLs in our Pneumatic Tool and Accessories Category through our line of Tru-Flate products. After all, a job well done starts with well-maintained tools, and we're here to help you achieve just that with quality parts.